Project Background:

- Product Series: Architect Pro Pergola | 2117

- Project Location: Gold Coast Hotel, Australia

- Project Time: 2022

The Seabreeze Resort Hotel, located on Australia’s Gold Coast, sought to upgrade its outdoor space. While the beachfront views are highly appealing, the pool area often remains empty during peak sunlight hours. Guests enjoy the scenery but lack suitable shade, making prolonged stays uncomfortable.

What they needed was a durable, stylish, and practical pool pavilion to bring the space to life.

How They Found Us?

The hotel’s operations manager began searching online for keywords like “pool pergolas” and “Hotel Shade structures.” That’s how they found us—Progolas. They browsed our website and were impressed by our modern designs. Our project designs are specifically tailored to Australia’s coastal conditions.

They were particularly drawn to our sleek, fully electric systems. We can customize these systems, including using a clean white pavilion finish to match their architectural style.

Project-Challenges

1. Salt Spray Corrosion:

High salt content in the air near the sea causes salt spray to easily adhere to metal surfaces, damaging the oxide layer on aluminum materials and potentially leading to corrosion or blistering of the coating over time.

2. High Humidity and Coating Aging:

High humidity in coastal areas can cause ordinary paint or anodized coatings to fade, chalk, or crack under prolonged damp conditions.

3. Strong Winds and Typhoon Season:

High wind speeds, especially during typhoon season, can easily cause structural deformation or loosening of ordinary awnings.

4. Ultraviolet Radiation and Heat Reflection:

Strong sunlight near the sea accelerates coating aging and may also cause indoor temperatures to rise.

5. Sea Wind Noise and Structural Stability:

Strong winds sweeping over louvers or beams may produce whistling sounds or slight resonance.

Our Solution:

Finally, our solution adopted a coastal-grade aluminum pergola solution:

- The main beams, columns, and louvered roof blades are made of 6063-T5 high-strength aluminum alloy, with a chromium-free conversion coating pretreatment throughout the process;

- The exterior system uses imported Dutch Akzo aerospace-grade powder coating;

- All exposed fasteners are 316/316L grade with insulating gaskets to ensure electrical safety;

- The structure is calculated according to Australian local standards and basic wind speed V=[xx] m/s (Exposure C/D) to ensure that the pergola can operate normally even in a Category 5 hurricane; and it features an integrated design with concealed drainage and 50–80 mm ventilation ducts.

How do we implement this? (From receiving inquiries to finalizing solutions and construction)

1,Requirement Confirmation & Project Initiation (T+0 to T+2 days)

- What we do: Conduct phone/video calls to discuss layout, dimensions, wind zones, color schemes, budget, and timeline; confirm coastal proximity (0–3km/3–10km zones).

- Client Provides: Site plan/elevation sketches or existing drawings, target dimensions/ceiling height, ground surface type (concrete/paving/wood deck), power source location, HOA/municipal permit requirements (if applicable).

- Deliverables: Proposal V1 (plan/elevation/rendering + cost estimate + preliminary schedule) and Site Survey Checklist.

2,Site Survey & Design Refinement (T+3 to T+6 days)

- On-site visit: Laser distance measurement + horizontal elevation, foundation rebound, drainage flow, obstacles, wind corridor; capture 360° reference imagery.

- Engineering actions: Preliminary wind load calculation (per ASCE7/local code), foundation method recommendations (individual footings/strip footings/chemical anchors), integrated drainage routing.

- Material Finalization:

Coastal zones 0–3km: Default AAMA 2605 coating + 316 fasteners; >3km may use 2604.

Color swatches and tactile samples confirmed in batch. - Deliverables:

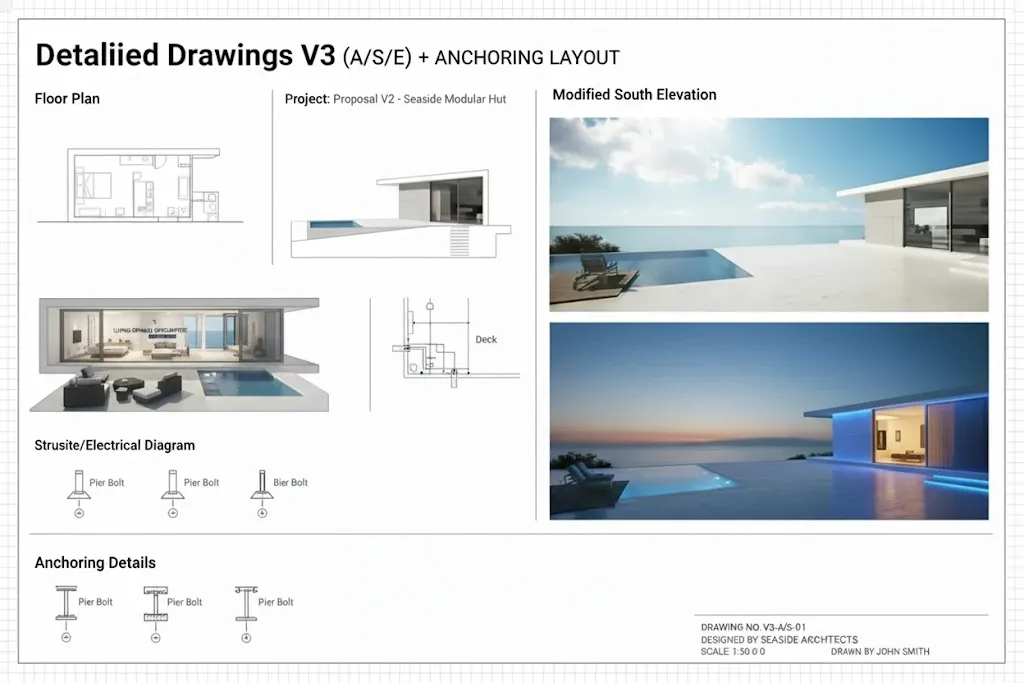

Survey Report, Detailed Drawings V2 (A/S/E) + Anchor Layout,

Wind Load & Construction Notes Summary, Storm Mode Operation Diagram.

3,Technical Review & Permitting (may run concurrently with Step 3)

- Structural Sign-off (if required): I liaise with registered structural engineer to produce foundation/anchor bolt calculations, load diagrams, and schedules.

- Government/Park Submissions: I compile submission package (material data sheets, coating standards, sample cards, installation manual, construction safety plan).

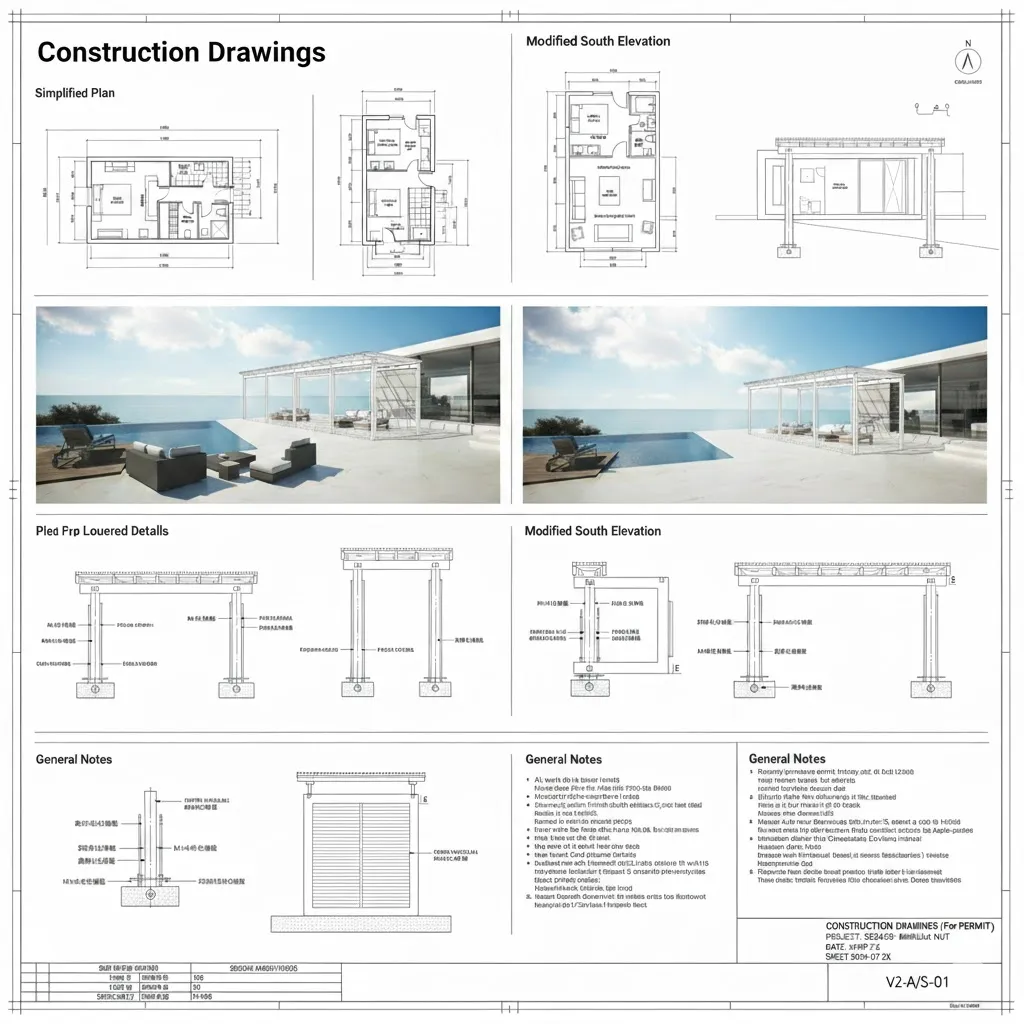

- Deliverables: Construction Drawings (For Permit), Material Data Sheets, Method Manual + JHA.

4,Contract & Order Placement & Master Schedule Freeze (T+7 to T8 days)

- I lead Kickoff: Freeze dimensions/BOM/colors; confirm power/drainage interfaces and foundation completion timeline; lock logistics routes and lifting points.

- Production scheduling: Raw material intake → Pre-treatment → Chromium-free passivation → Spraying/Anodizing → Curing → Final inspection; concurrently prepare stainless steel components, insulating plates, and seals.

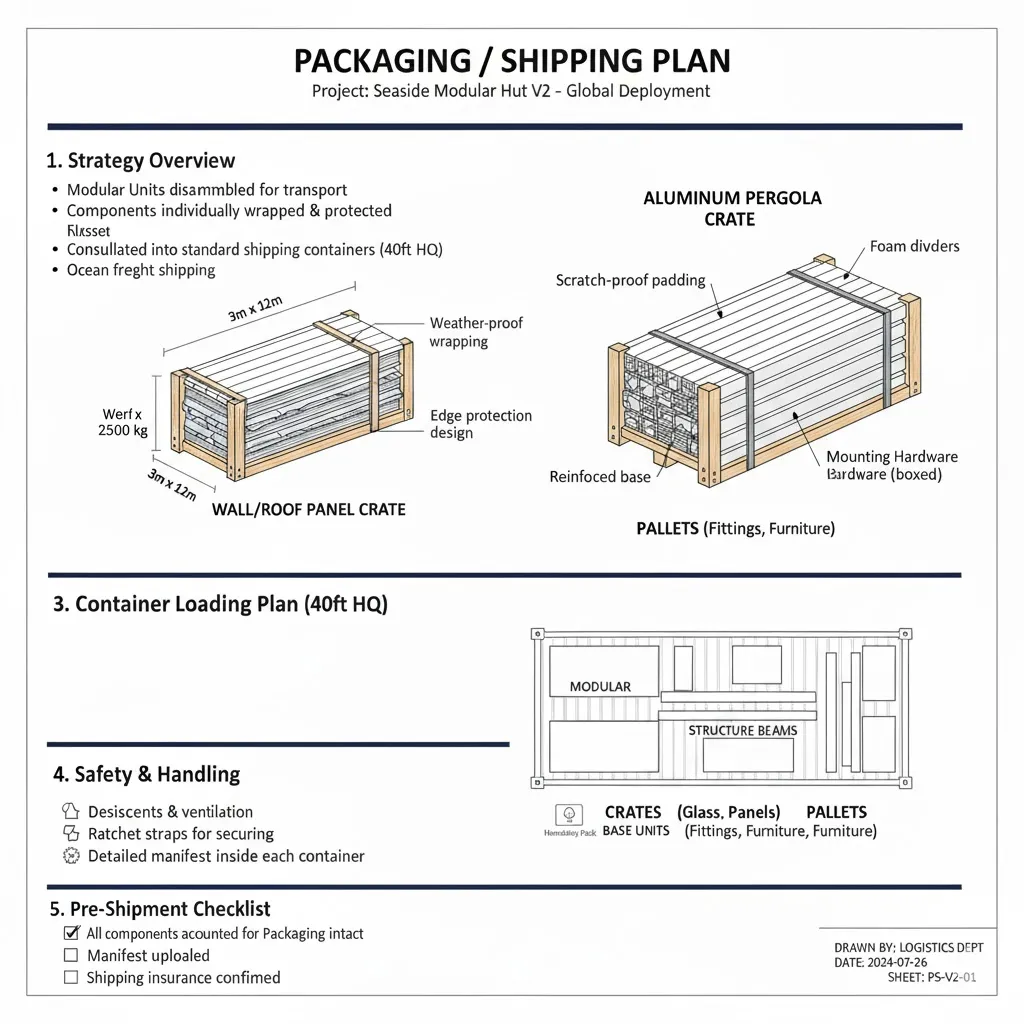

- Deliverables: Production Gantt Chart, Bill of Materials (BOM), Packaging/Shipping Plan, Warranty Terms.

How we deliver (from production, testing, installation, acceptance, and maintenance)

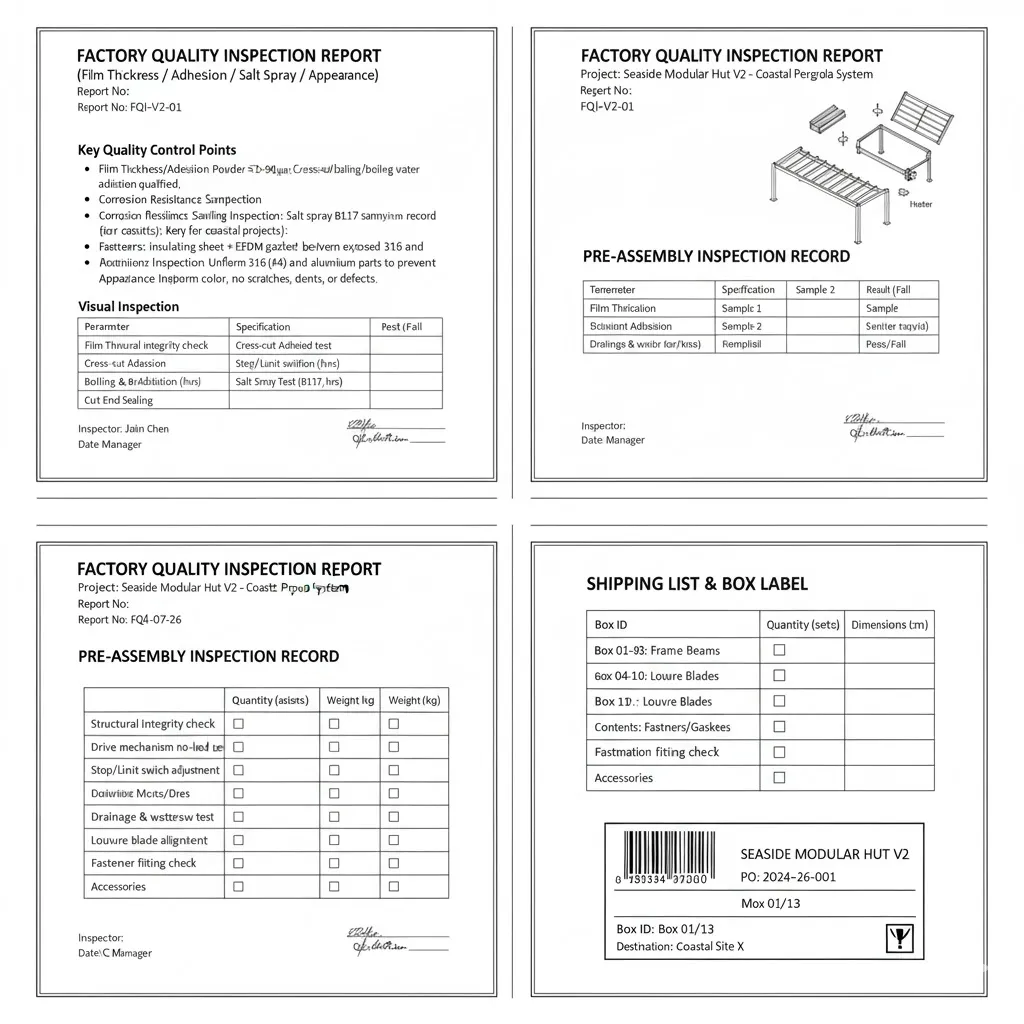

5,Manufacturing & Quality Control (T+8 to 10 days after step 3, varying depending on scale)

Key Quality Control Points:

- Film Thickness/Adhesion: Powder ≥70–90μm; Cross-cut adhesion/boiling water adhesion qualified.

- Corrosion Resistance Sampling Inspection: Salt spray B117 sampling inspection record (key for coastal projects); paint sealing at cut ends.

- Fasteners: Insulating sheet + EPDM gasket between exposed 316 (A4) and aluminum parts to prevent galvanic corrosion.

- Pre-assembly and Trial Run: No-load test run of drive mechanism, stop/limit adjustment, drainage and water flow test.

- Output: Factory Quality Inspection Report (including film thickness/adhesion/salt spray/appearance), Pre-assembly Inspection Record, Shipping List & Box Label.

6. Logistics & On-site Handover (T-3 to T-1 days before loading)

- Packaging: Vacuum-sealed moisture-proof bags + desiccant + wooden crates; corner protectors added to critical surfaces.

- On-site Handover: I and the on-site supervisor will check and receive goods according to the packing list/pallet number, take photos for archiving; consumables and spare parts will be separately labeled.

- Output: “Arrival Inspection Form (with photos)”, “Packing List”, “Damage/Missing Material RFI Process”.

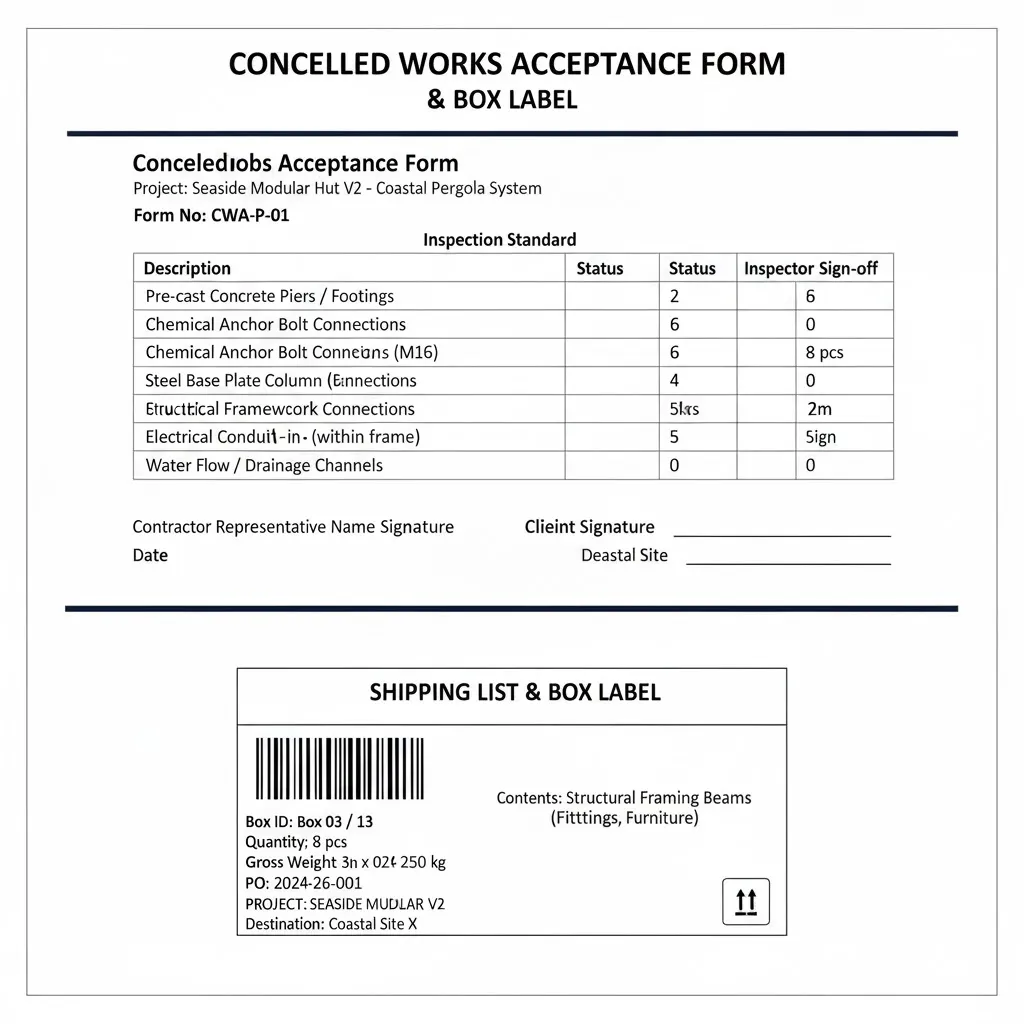

7. Foundation and Pre-embedded Works (Can be done by civil engineering first)

- Foundation Construction: Prioritize penetrating the brickwork to the concrete; independent foundations should be constructed according to the dimensions/reinforcement/concrete grade shown in the drawings; chemical anchors M12–M16 (316) will be accepted based on curing time and pull-out value.

- Concealed Works Acceptance: Foundation pit inspection, reinforcement and anchor positioning, pull-out test records.

- Output: “Concealed Works Acceptance Form”, “Anchor Bolt Pull-out Record”.

8. Installation (Standard single unit: 3-5 days; Multi-unit/irregular shapes: adjusted according to scale)

Daily Plan

- Day 1: Laying out lines → Column/anchor fixing → Beam positioning.

- Day 2: Louvers/linkage mechanism → Motor → Drainage/cable routing.

- Day 3: System debugging → Storm Mode mechanical locking → Edge finishing/drip finishing.

Key Controls:

- Torque: Verify each item according to the Torque Table and mark with a pen.

- Drainage: Gutter cleaning → Water flow test (sprinkler/water pipe, confirm water outlet from column).

- Electrical and Control: Limit switches/obstruction protection/rain control linkage (if installed).

- Noise reduction and anti-loosening: EPDM vibration isolation, silicone cushioning, adhesive.

- Output: Water flow/trial operation record.

9. Joint Commissioning & Delivery Acceptance (1 day)

- I will guide you through the inspection item by item:

- Appearance: Coating, edge finishing, seam alignment, scratch/dent repair;

- Structure: Anchor quantity/specification/torque;

- Function: Opening/closing/stopping/obstruction detection/leakage points;

- Storm Mode: Blade 90°, mechanical locking in place。