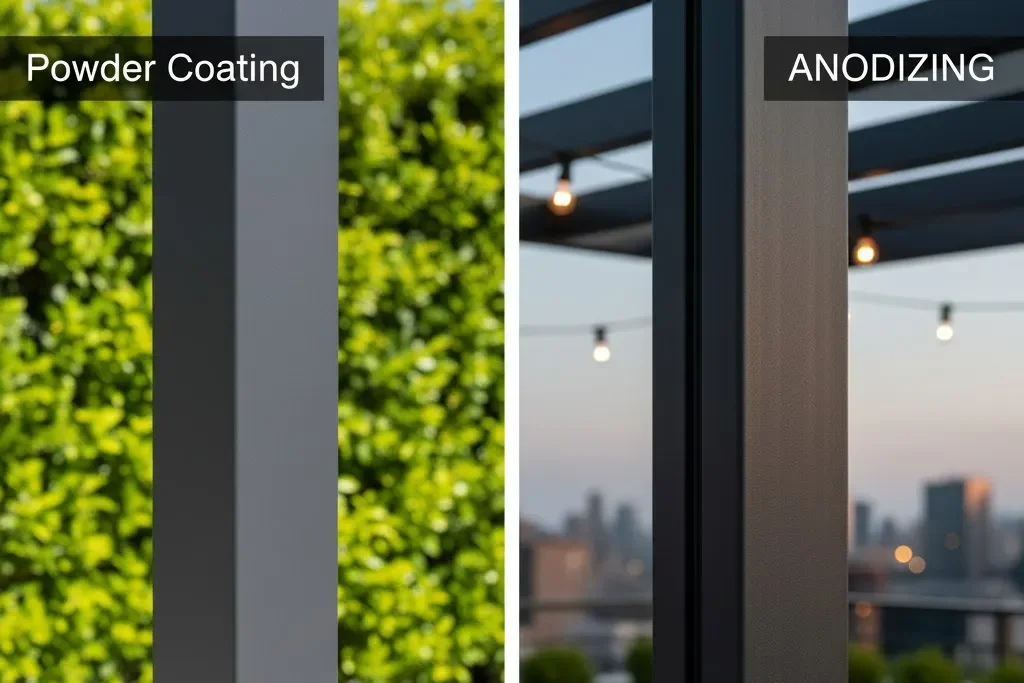

Powder Coating vs. Anodizing: The Ultimate Pergola Finish Guide

When you choose to install an aluminum pergola, you’re investing not only in its longevity but also in increasing the value of your property.

Therefore, choosing a high-strength surface treatment is crucial. It not only protects your pergola from weathering but also determines its color and texture.

The Core Dilemma

In the world of high-end aluminum finishes, two champions stand out: Powder Coating vs Anodizing. Both are vastly superior to simple liquid paint, but they are fundamentally different processes with distinct advantages and disadvantages.

So, is powder coating better than painting? Unquestionably, yes. But is it better than anodizing for your pergola?

Your Definitive Guide

This comprehensive guide will walk you through everything you need to know. We’ll explain what each finish is in simple terms, compare them head-to-head on the factors that matter most, and answer all your niche questions, from how to clean powder coated metal to how to remove anodizing. By the end, you’ll understand why one of these finishes has become the undisputed gold standard for high-quality outdoor structures.

What Is Powder Coating?

Simply put, giving your pergola a durable, colorful suit of armor that’s baked on for maximum toughness is powder coating.

It’s a modern, environmentally friendly finishing process where a fine powder—a mixture of polymer resins, pigments, and other additives—is applied to the aluminum.

But what is powder coating made of?

It’s a dry powder, not a liquid paint. The magic lies in how it’s applied.

The Electrostatic Charge

The aluminum parts are grounded, and the powder is given a positive electrostatic charge. This charge makes the powder cling to the metal surface like a magnet.

The Curing Process

The parts are then moved into a large curing oven. The high powder coat temp (typically around 400°F / 200°C) causes the powder to melt, flow together, and form a continuous, incredibly durable, and beautiful finish that is much thicker and stronger than traditional paint.

This entire process is expertly explained by industry authorities like the Powder Coating Institute.

What Is Anodizing?

Anodizing is a completely different, fascinating process. Instead of applying a separate layer on top of the aluminum, anodizing creates a protective layer from the aluminum itself.

Think of it this way: through an electrochemical process, you are encouraging the aluminum to grow”its own super-hard, transparent, protective skin.

The Electrochemical Process

The aluminum part is submerged in an electrolytic acid bath, and an electric current is passed through it. This forces the surface of the aluminum to oxidize in a controlled, uniform way, creating an anodic coating that is fully integrated with the metal beneath it. This layer is exceptionally hard and resistant to abrasion.

For a deeper scientific explanation, the Aluminum Anodizers Council provides excellent resources.

The Head-to-Head Comparison: Powder Coating vs. Anodizing

Now that we know what they are, let’s compare them on the criteria that matter most for an outdoor pergola.

| Feature | Powder Coating | Anodizing |

|---|---|---|

| Color & Appearance | Excellent (Virtually unlimited colors, multiple textures) | Limited (Metallic sheen, few color options) |

| Durability (Abrasion) | Good to Excellent | Superior (Extremely hard surface) |

| Corrosion Resistance | Excellent | Excellent (but can be vulnerable to acids/alkalis) |

| UV Resistance / Fade | Excellent (with high-grade powders) | Good (but some dyes can fade over time) |

| Environmental Impact | Excellent (No VOCs) | Moderate (Process is energy-intensive) |

| Cost | Moderate to High | Moderate to High |

Color & Appearance

Powder Coating:

Offers virtually unlimited color choices, from standard blacks and whites to any custom color imaginable. It also provides a wide range of finishes, including matte, satin, gloss, and even textured surfaces. This versatility is critical for matching a pergola to a home’s specific architectural style.

Anodizing:

Provides a distinct, metallic luster that many find appealing. However, the color palette is extremely limited, typically to clear (natural silver), bronze, and black. The finish is translucent, meaning the underlying metal’s character is always visible.

Durability & Abrasion Resistance

Powder Coating:

Creates a thick, tough, and flexible finish that is highly resistant to chipping and scratching in everyday use. For an architectural application like a pergola, its durability is more than sufficient for a lifetime of performance.

Anodizing:

Creates a surface that is exceptionally hard and integrated with the aluminum itself. It is superior in terms of pure abrasion resistance, making it ideal for high-wear industrial components.

Corrosion Resistance

Powder Coating:

Excellent. It creates a complete, non-porous barrier that completely seals the aluminum from moisture, salt spray, and other corrosive elements. It acts as an impermeable shield.

Anodizing:

Excellent. The dense oxide layer is naturally resistant to corrosion. However, this layer can be damaged by harsh chemicals, acid rain, or alkalis (like mortar), which can compromise its long-term protective qualities.

UV Resistance & Color Stability

Powder Coating:

Excellent, especially when using high-performance, architectural-grade polyester powders (meeting AAMA 2604/2605 standards). These are specifically formulated with UV inhibitors to provide outstanding, long-term resistance to fading, even in intense sun.

Anodizing:

Good. The clear anodic layer itself is perfectly UV stable. However, the organic dyes used to create colors can be prone to fading over many years of direct, harsh sun exposure.

Environmental Impact

Powder Coating:

Excellent. The process releases near-zero Volatile Organic Compounds (VOCs) into the atmosphere. Unused powder can also be collected and reused, creating very little waste.

Anodizing:

Moderate. While the final product is stable, the process itself is energy-intensive and involves the use of acid baths and other chemicals that require careful environmental management.

Cost

Powder Coating:

Considered a premium finish, with costs that are moderate to high depending on the quality of the powder and the complexity of the process.

Anodizing:

Also a premium process. Costs are generally comparable to high-quality powder coating, varying based on the desired thickness and color of the anodic layer.

Inside the Progolas Lab: How We Test Our Finishes

At Progolas, we don’t just rely on our suppliers’ data sheets. Our internal quality control lab continuously validates the performance of our finishes to ensure they meet our exacting standards.

QUV Accelerated Weathering

We place coated samples in our QUV accelerated weathering tester. This machine bombards the samples with intense UV radiation and simulated rain cycles, condensing years of outdoor exposure into weeks. Our experience shows that AAMA 2604-compliant powders consistently maintain their color and gloss, while lower-grade finishes begin to fail rapidly.

Salt Spray Testing

Our salt spray chamber mimics the harsh conditions of a coastal environment, continuously spraying a heated salt fog onto the samples. This allows us to see with our own eyes how different finishes hold up against corrosion. This hands-on testing confirms that a properly pre-treated, AAMA 2604 powder-coated surface provides a superior protective barrier.

This rigorous internal testing is why we are confident in the long-term durability of our chosen finishing system.

Why Powder Coating is the Superior Choice for Pergolas

While anodizing is an excellent finish for certain industrial and high-wear applications, powder coating is the clear winner for high-end aluminum pergolas.

The Reason Is Simple:

It offers the best combination of benefits for an architectural product that must be both incredibly durable and aesthetically versatile. The unlimited color choice, superior UV resistance of premium powders, and robust, all-around corrosion protection make it the perfect skin for a structure that needs to look beautiful and perform flawlessly for decades. It delivers on the promise of a truly low-maintenance, high-value investment.

That’s why at Progolas, all our systems are protected by a high-performance powder coating—it’s part of our commitment to lasting quality you can see and feel.

For more on our material philosophy, you can read our deep dive on Why T6063 Aluminum is the Gold Standard for Pergolas.

Maintenance & Cleaning: Keeping Your Finish Pristine

The beauty of both finishes is their low maintenance.

How to clean powder coated metal

The best method is the simplest: a soft cloth or sponge with mild soap and water. Rinse thoroughly. Never use abrasive cleaners, harsh solvents, or pressure washers at close range, as they can damage the finish.

How to clean anodized aluminum

Similar to powder coating, use only mild detergents. Anodized surfaces can be damaged by acidic or alkaline cleaners. It’s also important to know how to polish anodized aluminum—in most cases, you shouldn’t. Aggressive polishing can remove the protective anodic layer.

Repair, Removal & Repainting: A Homeowner’s Guide

Damage can happen. Here’s what you need to know.

How to remove powder coat

This is a difficult task for a DIYer. Professionally, it’s done through chemical stripping or media blasting. There are some products marketed as a good stripper that will take off powder coat, but they are often harsh chemicals that require extreme care. For a small scratch, it’s far better to use a touch-up paint pen provided by the manufacturer.

Can you paint anodized aluminum?

Yes, but it requires meticulous preparation. The surface must be scuffed (sanded) and a special self-etching primer must be used to ensure the new paint will adhere to the hard, smooth anodic layer. Simply painting over it will likely result in peeling.

The Ultimate Combination: Powder Coating Over Anodizing

Can you powder coat anodized aluminum? Yes, and this two-step process is considered the gold standard for ultimate durability in the most extreme environments, like coastal or industrial settings. The anodized layer provides a perfect, corrosion-free base, and the powder coat provides the color and superior UV protection. While it’s an expensive process, it’s a testament to the fact that powder coating is seen as the ultimate top layer of defense.

Tips: To learn more about how brands deliver on their quality promises, check out our Ultimate Guide to Choosing a Pergola Brand.

Frequently Asked Questions (FAQ)

Q1: How long does powder coating last on aluminum?

A high-quality, architectural-grade powder coat on a properly pre-treated aluminum surface can last 15-20 years or even longer before showing any significant signs of fading.

Q2: Does powder coating prevent rust completely?

On aluminum, yes. Since aluminum doesn’t rust in the first place, the powder coat acts as a complete seal against any form of corrosion. On steel, it creates a powerful barrier, but if that barrier is deeply scratched, the steel underneath can be exposed and rust.

Q3: Will anodized aluminum rust or corrode?

No. Aluminum does not rust (rust is iron oxide). Anodizing enhances its natural corrosion resistance, but it can still be damaged and show pitting if exposed to harsh acids or alkalis.

Q4: How thick is a typical powder coat?

A typical architectural powder coat is between 2-4 mils (thousandths of an inch) thick, which is significantly thicker and more durable than a layer of liquid paint. For more in-depth standards, you can refer to guidelines from the Architectural Metal Finishing standards by AkzoNobel.

Q5: Can you powder coat wood?

Traditionally, no, because the high curing temperature would destroy the wood. However, some new low-temperature powder coating technologies are emerging for heat-sensitive materials.