Introduction : 3 points sensibles majeurs pour les constructeurs lors du choix d'un système de pergola (le vivez-vous également ?)

En tant que constructeur d'un projet de villa, rencontrez-vous souvent ces problèmes :

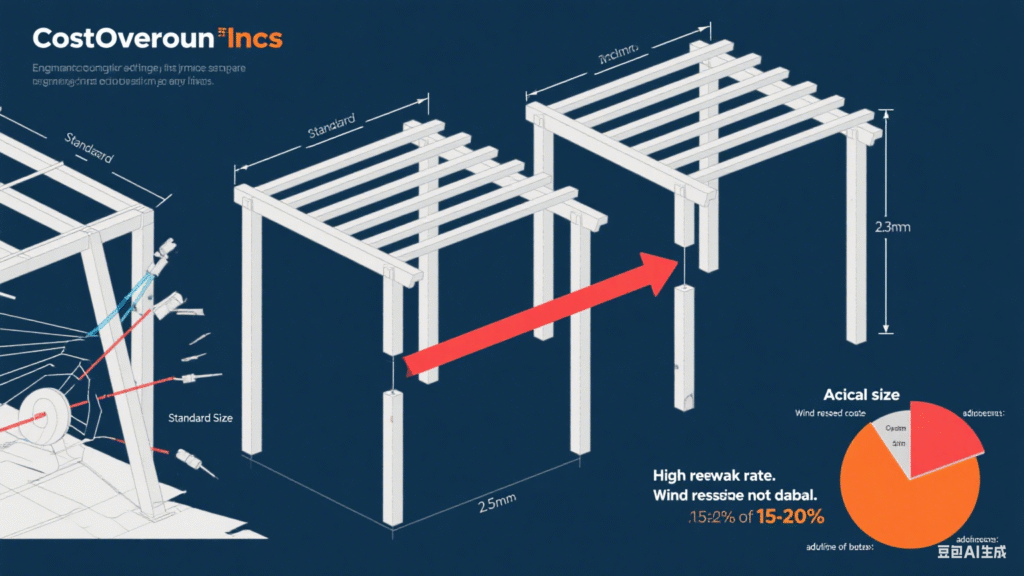

- Dépassement de coût : Le taux de reprise de l'installation de la pergola est élevé (dimensions incohérentes, résistance au vent inférieure aux normes) et les dépenses supplémentaires représentent 15% à 20% du budget du projet.

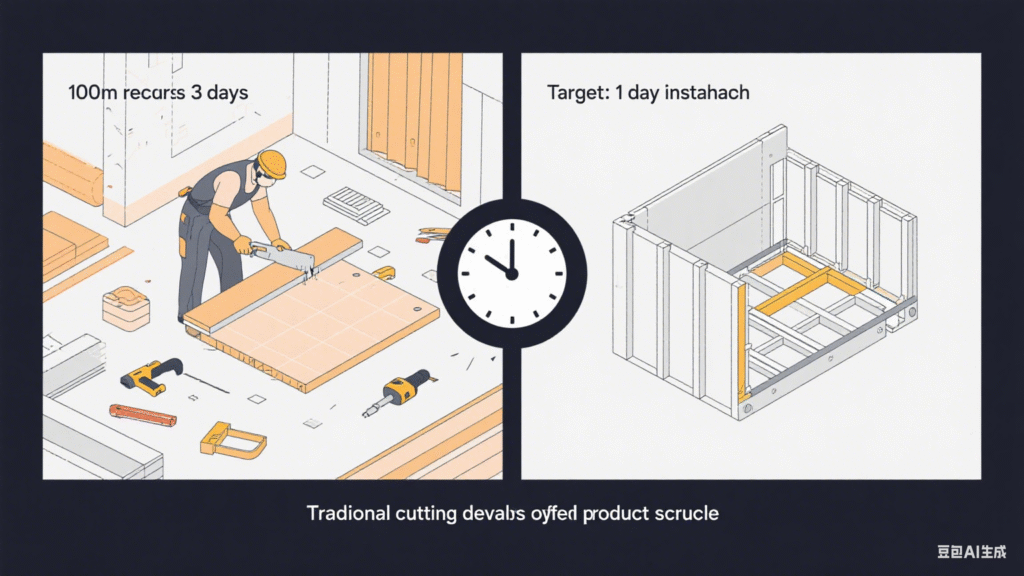

- Retard de construction : les pergolas traditionnelles prennent du temps à couper sur place, et un projet de 100㎡ prend 3 jours, ce qui affecte l'avancement global de la livraison ;

- Plaintes des clients : Après avoir emménagé, le propriétaire a signalé que la pergola fuyait et se décolorait, et les litiges après-vente ont pris beaucoup d'énergie et ont même affecté la coopération ultérieure.

Nous avons servi plus de 50 constructeurs américains (des constructeurs de maisons personnalisées en Californie aux grands projets de développement au Texas) et avons constaté que le choix du bon système de pergola en aluminium peut résoudre 80% des problèmes.

Ce sujet va démonter : Comment réduire les coûts grâce à la « conception modulaire » du 30%, réduire les retouches grâce à la « certification de conformité » et raccourcir la période de construction grâce à une « installation rapide » et, en fin de compte, augmenter les marges bénéficiaires du projet.

1. Pourquoi la pergola en aluminium est-elle un outil rentable pour les constructeurs ? (3 principaux avantages)

Pour les constructeurs, les pergolas ne sont pas des « décorations supplémentaires », mais des « éléments clés qui influencent l'efficacité et la réputation du projet ». Les avantages des systèmes en aluminium de haute qualité se reflètent directement sur la rentabilité :

- Réduire les coûts de construction: La conception modulaire réduit les déchets de 30%

Les pergolas traditionnelles nécessitent une découpe et un soudage sur site, et le taux de perte de matériau atteint des valeurs allant de 10% à 15% (en particulier pour les dimensions spéciales). Systèmes modulaires en aluminium (comme notre série « ProFit ») :

Les pièces standard préfabriquées en usine (colonnes, poutres et cadres supérieurs sont produits en série selon des tailles courantes), doivent uniquement être assemblées sur site et le taux de perte est réduit à moins de 3% ;

Évitez les mauvaises coupes et les reprises: faire correspondre le modèle BIM avec les dessins architecturaux à l'avance, et l'erreur de taille est ≤ 1 mm (joint avec le cas d'un constructeur de l'Arizona : 10 projets de villa économisent $24 000 en coûts de matériaux).

- Réduire la période de construction : 2 personnes réalisent l'installation d'une pergola en 1 jour (efficacité augmentée de 200%)

Les pergolas traditionnelles à structure bois/acier (nécessitant un traitement anticorrosion, soudure, peinture) nécessitent 3 ouvriers pour réaliser un projet de 100㎡ en 3 jours, tandis que le système en aluminium :

Pas besoin de peinture sur place (le traitement de surface par pulvérisation de poudre est effectué en usine) ;

Connexion encliquetable:2 ouvriers peuvent terminer l'installation en 1 jour (joint avec un tableau comparatif du processus de construction : traditionnel 3 jours vs aluminium 1 jour), réduisant directement les coûts de main-d'œuvre de 60%.

- Réduire les litiges après-vente: La conformité et la durabilité améliorent la satisfaction client

Le plus gros problème pour les constructeurs réside dans les « réclamations après livraison ». Le système de pergola en aluminium résout ce problème grâce à deux points :

Certification de conformité totale:Il est conforme aux codes du bâtiment de divers États des États-Unis (tels que la norme de résistance aux ouragans de 130 mph de la Floride et la classification au feu de classe A de la Californie), et le taux d'approbation HOA est de 100% ;

Garantie de 20 ans : Le matériau est résistant à la corrosion et à la décoloration, et le taux de satisfaction client est de seulement 2% (contre 15% pour les pergolas en bois traditionnelles). Un constructeur texan a rapporté après utilisation : « Les réclamations clients ont diminué de 80%, et l'énergie peut être consacrée à de nouveaux projets. »

2,4 normes techniques majeures pour les constructeurs pour choisir un système de pergola en aluminium (éviter les pièges)

Toutes les pergolas en aluminium ne conviennent pas aux projets, et les constructeurs doivent se concentrer sur les « détails techniques qui peuvent affecter directement la construction et le coût » :

(1),Résistance structurelle : Le niveau de résistance au vent doit correspondre à l'emplacement du projet

Régions enneigées du Nord (comme New York et le Michigan) : sélectionnez un système avec une « résistance à la charge de neige ≥ 20 psf » et une épaisseur de cadre principal ≥ 3,0 mm ;

Zones d'ouragan du Sud (Floride et Louisiane) : exigent un « niveau de résistance au vent ≥ 130 mph » et une profondeur des pièces encastrées ≥ 48 pouces (joints avec un tableau comparatif des normes de résistance au vent pour chaque État des États-Unis) ;

Méthode de vérification : exiger des fournisseurs qu'ils fournissent des « rapports de test ASTM tiers » pour éviter les « promesses verbales »

(un constructeur a été condamné à une amende et a été retravaillé en Floride pour avoir utilisé un système de « résistance au vent de 110 mph »).

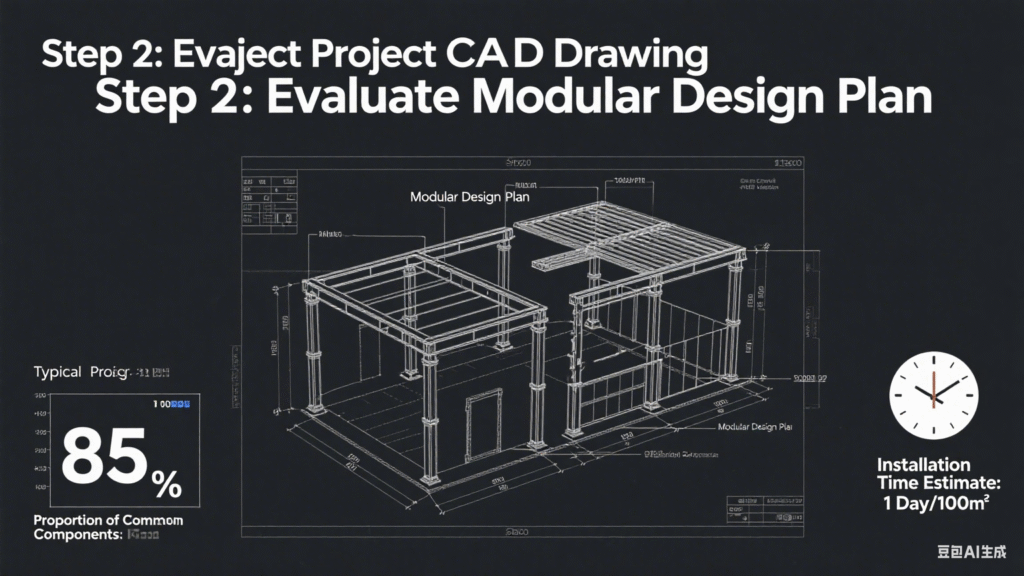

(2) Modularité : Examinez le « ratio des composants communs » (plus le ratio est élevé, plus vous économisez d'argent)

Le rapport des composants communs d'un système de haute qualité est ≥ 80% (tels que les colonnes et les connecteurs qui peuvent être réutilisés dans plusieurs projets), ce qui réduit la pression sur les stocks :

Exemple : La « série électrique » comporte 5 longueurs de colonnes courantes (8 pieds/10 pieds/12 pieds) et 3 largeurs de cadre supérieur, couvrant 90% de types de villas ;

Évitez les pièges : méfiez-vous des systèmes avec des « taux de personnalisation trop élevés » (par exemple, plus de 30% de composants doivent être moulés séparément), ce qui augmentera les coûts d’approvisionnement de 20%+.

(3),Efficacité de l'installation : si elle prend en charge la « construction à base zéro » (réduction de la dépendance à l'égard des travailleurs qualifiés)

Les constructeurs sont souvent confrontés au problème de l'instabilité des compétences des travailleurs. Un bon système devrait assurer les fonctions suivantes :

Fournir un « manuel d’installation infaillible » (comprenant des schémas 3D étape par étape et des paramètres de clé dynamométrique), afin que les nouveaux travailleurs puissent démarrer après 2 heures de formation ;

Equipé d'outils spéciaux (tels que des clés à démontage rapide), il est 3 fois plus rapide que la fixation par vis traditionnelle.

(4) Documents de conformité : « Toutes les certifications requises pour l’acceptation du projet » peuvent-elles être fournies rapidement ?

L'une des étapes les plus chronophages pour les constructeurs est la préparation des documents de réception. Les fournisseurs de qualité doivent préparer à l'avance :

- Certifications du code du bâtiment de l’État (telles que la certification Miami-Dade en Floride et la certification d’économie d’énergie Title 24 en Californie) ;

- Rapports d'essais de matériaux (composition de l'alliage d'aluminium, résistance du revêtement aux intempéries, données d'essai de résistance au vent) ;

- Modèle d'approbation HOA (y compris les dessins de conception CAO et les descriptions de style, qui peuvent être soumis directement à l'association des propriétaires).

3,5 « normes cachées » pour que les constructeurs choisissent leurs fournisseurs (plus importantes que le prix)

Pour les constructeurs B-end, la fiabilité du fournisseur influence directement la réussite ou l'échec du projet. Outre le produit lui-même, cela dépend également :

- Inventaire localisé : s'il peut être « livré sur le site du projet dans les 48 heures » (le coût logistique aux États-Unis est élevé et la perte causée par les retards de rupture de stock est bien supérieure à la différence de prix) ;

- Support technique: si « l'ancrage de la conception CAO pré-projet » est fourni (évitant les erreurs de taille), « un guidage 1 à 1 pendant l'installation » (résolution à distance des problèmes soudains) ;

- Remise sur achat en gros : s'il existe un prix échelonné pour les achats annuels dépassant 50 ensembles (par exemple, 15% de réduction pour plus de 100 ensembles, réduisant ainsi les coûts à long terme) ;

- Ressources marketing conjointes : si un « manuel du propriétaire » et un « guide d’entretien de la pergola » peuvent être fournis (améliorant ainsi la satisfaction du client final et aidant indirectement les constructeurs à maintenir les relations) ;

- Rapidité de réponse après-vente: si le fournisseur peut être contacté dans les 24 heures pour demander des solutions au problème (comme des pièces endommagées, si elles peuvent être rééditées en urgence pour éviter d'affecter la livraison).

4. Guide d'action : Comment les constructeurs peuvent-ils tester rapidement l'adaptabilité des systèmes de pergola en aluminium ?

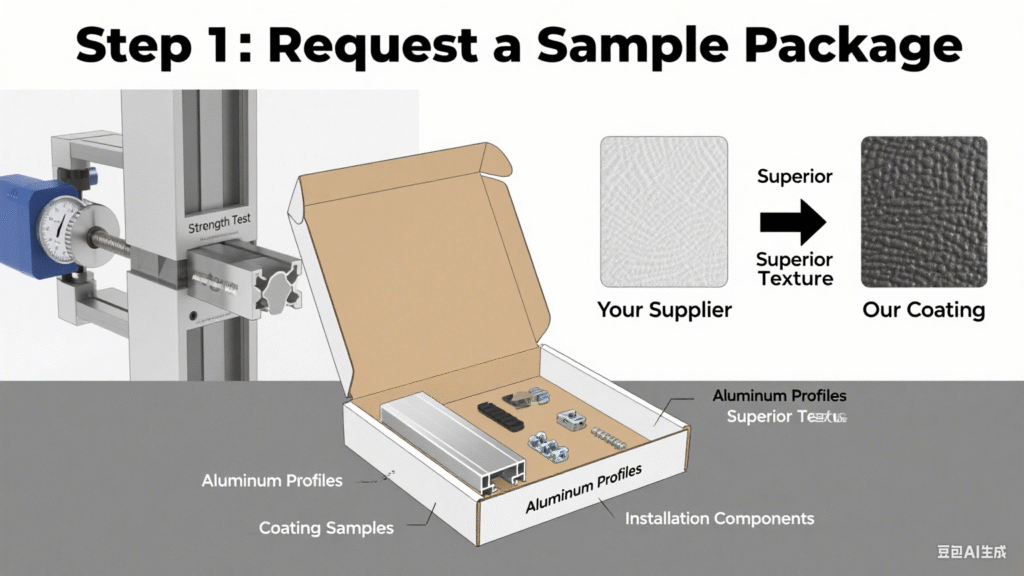

Étape 1 : Demandez un « pack d’échantillons » (comprenant des profilés en aluminium, des échantillons de revêtement et des composants d’installation) pour tester la résistance du matériau et la texture du revêtement (par rapport à vos fournisseurs existants) ;

Étape 2 : Fournir un dessin CAO d'un projet typique et demander au fournisseur d'émettre un « plan de conception modulaire » pour évaluer la « proportion de composants communs » et « l'estimation du temps d'installation » ;

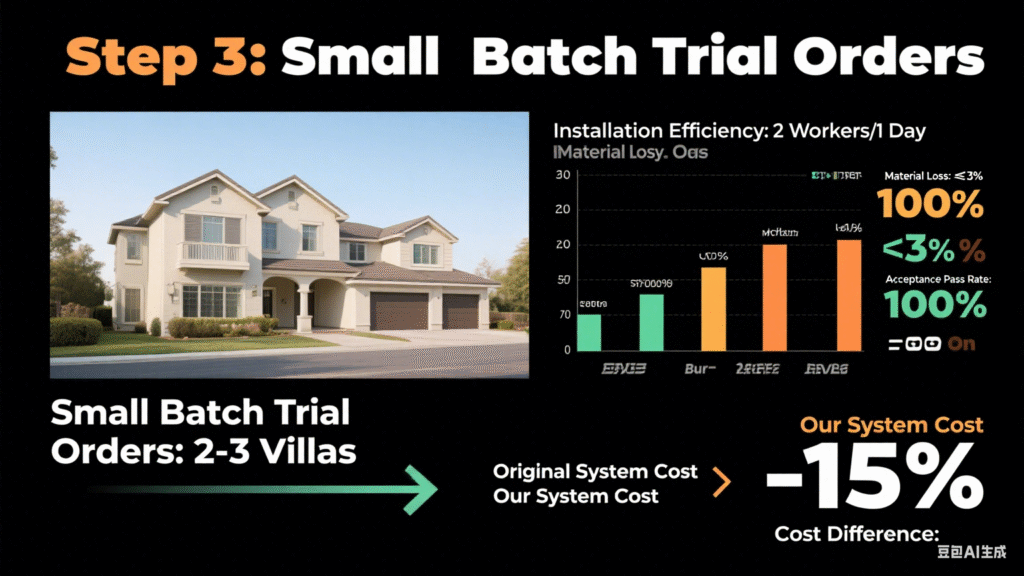

Étape 3 : Commandes d'essai en petits lots (par exemple 2 à 3 villas), enregistrement de « l'efficacité de l'installation », de la « perte de matériel » et du « taux de réussite à l'acceptation » et comparaison de la différence de coût avec le système d'origine ;

Étape 4 : Signez un accord de coopération à long terme pour garantir des « remises sur les achats en gros » et des « droits d’approvisionnement prioritaire » (en particulier pendant les périodes de pointe pour éviter les ruptures de stock).

Conclusion : Le système de pergola n'est pas un « élément de coût » mais un « point de croissance du bénéfice »

Pour les constructeurs, choisir le bon système de pergola en aluminium peut non seulement résoudre les anciens problèmes de « coût, de période de construction et d'après-vente », mais également gagner la reconnaissance des propriétaires en « améliorant la qualité du projet » - c'est la clé de la rentabilité à long terme.

Agissez maintenant : Cliquez pour recevoir la « boîte à outils de sélection de pergolas en aluminium exclusive du constructeur » (comprenant : des tableaux de normes de conformité de l'État, des modèles d'estimation des coûts et 10 cas de conception de projets de villa), et les 20 premiers constructeurs peuvent bénéficier gratuitement d'une « formation à l'installation sur site ».

Quels problèmes avez-vous rencontrés avec votre système de pergola dans votre projet actuel ? Laissez-nous un message pour décrire vos difficultés et nous vous proposerons des solutions ciblées.